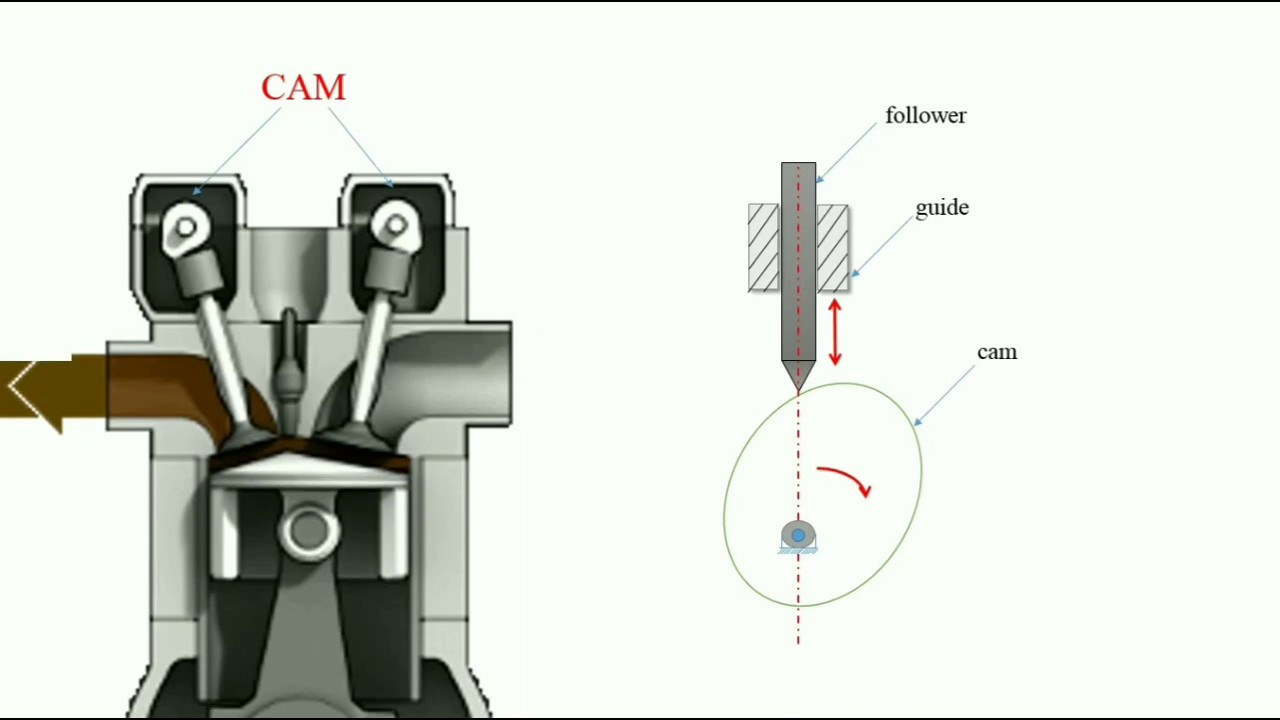

They are used in many applications from combustion engines through milling machines to fitness machines. The apparatus used is the cam and tappet apparatus with roller domed and flat followers equipped with dial indicator.

What Are Cam And Follower Types Working Terminology Application Notes Pdf

Attention to the front and rear view position of the cam as the cam guiding rod bore hole is situated on the rear of the cam.

. Follower inhibits the push and pulls of the Cam. The contact force model for. 625 Examples in SimDesign.

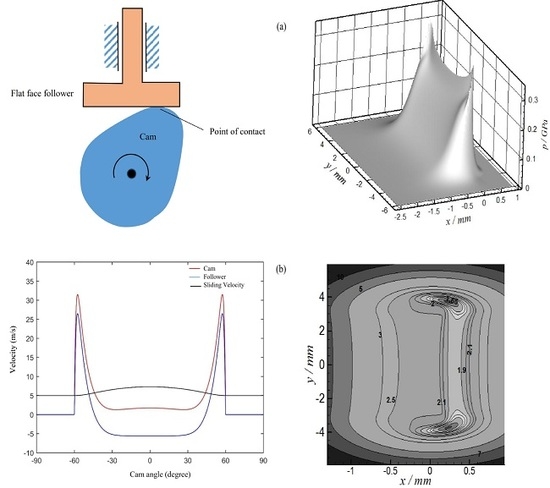

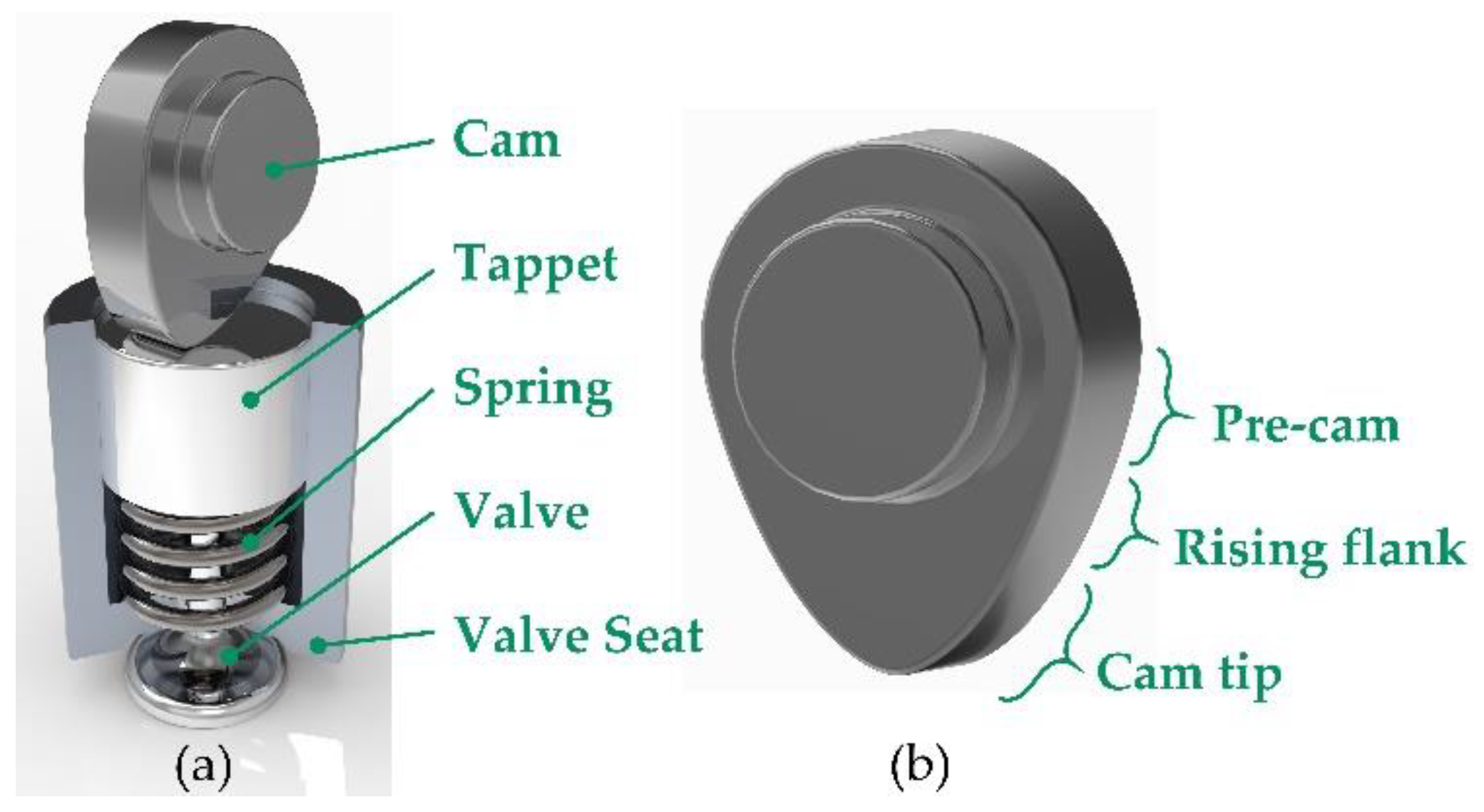

Loosen the fixing screw 23 with the provided Allan key and insert the flat tappet followeApply a thin film of grease to the flat tappet. Owing to the contact point changing between cam and tappet tappet stiffness S t can be expressed by the equation. Attention to the front and rear view position of the cam as the cam guiding rod bore hole.

Universiti Tenaga Nasional 2006 Mechanical Design and CAD Laboratory CAM AND TAPPET EXPERIMENT OBJECTIVE The objective of the experiment is to investigate tappet motion for several different cam profiles and to study the effect of different followers. 2 S t A s 2 B s S 0 where s is the eccentricity and A B S 0 are the constants which can be calculated by assuming the stiffness of three points as shown in. The various test procedures employed in the experimental program are shown in Table 2.

The engine vibration and noise induced by a valve train element are analyzed through the modeling and experiment method. Tappet cam and wipers are names given indiscriminately to those irregular pieces of mechanism to which a rotary motion is given for the purpose of producing by sliding contact. Made available by US.

Data Observation and Results. The stiffness value of the upper stem and the lower head were about 28 kNmm and 36 kNmm. The preview shows page 2 - 4 out of 9 pages.

Tappets are generally used for heald shedding. Loosen the fixing screw 23 with the provided Allan key and insert the flat tappet follower. Day and Date experiment performed.

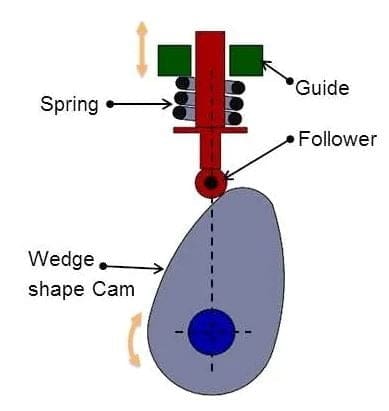

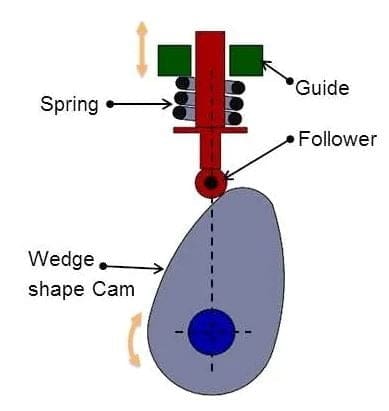

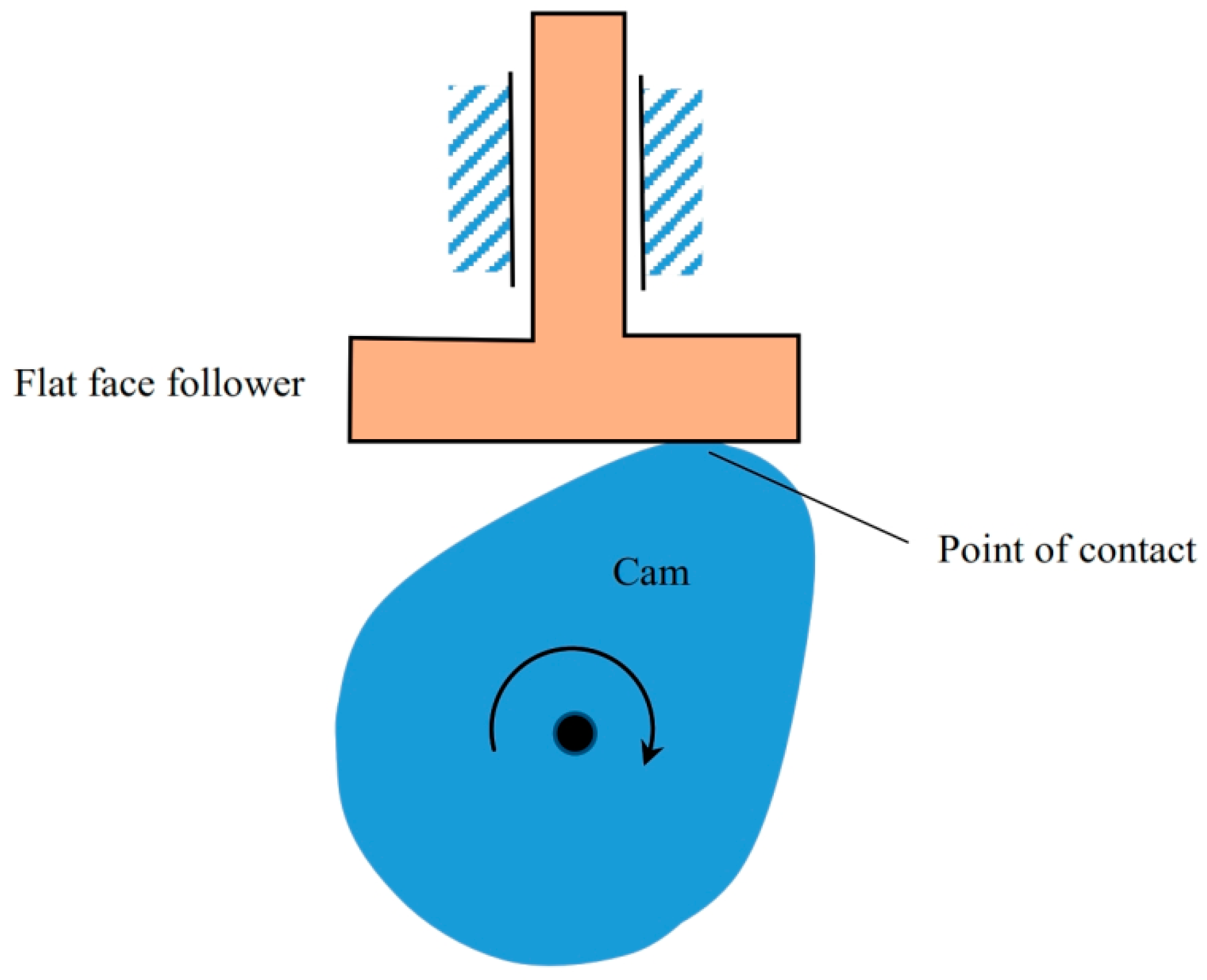

A follower is a mechanical component concerning which the Cam rotates in an oscillatory or circular motion. Experimental evaluation of tappetbore and camtappet friction for a direct acting bucket tappet valvetrain. When the rod is to receive a series of lifts with intervals of rest and thus forms.

THEORY Introduction Cams are widely used in engine machine. TEHL camtappet-contact of the valve train. Rotating Cam Translating Follower.

Study on tappet shedding mechanism. CAM AND TAPPET EXPERIMENT Objectives The objectives of this experiment are. The experimental results showed high sliding during contact with the cam base circle up to 20.

Statement of Purpose Objective. The mechanism for Cam and the mechanism for Follower depend. The objective of the experiment is to.

Situated on the rear of the cam. Tappetbore friction and torque at the camshaft were measured for a direct acting bucket tappet using a camtappet friction apparatus. A cam and tappet mechanism including a rotary cam a tappet a roller rotatably mounted upon the tappet for line contact with the cam and a plunger part guided for movement in a plane substantially at right angles to the axis of rotation of the cam the plunger part being contacted by the tappet to effect the movement said roller being of.

Tappetbore and camtappet friction torque and friction coefficient as a function of cam angle were derived from those measurements. - Investigate tappet motion for several different cam profiles and to see the effect of different followers. To compare the velocity profile of two cams simple harmonic parabolic cam and tangent cam 3.

Each cam has its own roller but the rollers are mounted on the same reciprocating or oscillating follower. Figure 6-7 Dual cam. As suggested by their range of.

Any sudden movement to the dial indicator stem was avoided. The Follower rotates in an oscillating or circular arc. The laboratory test installations are very simple since.

The two knurled nuts were undo and the two washers were removed. Tappet is a type of cam to which a rotary motion is given for the purpose of producing reciprocating motion in rods and levers by sliding contact. Six different types of cam and lifter combinations were used.

A tappet is a cam having some dwell period which controls the updown movement of heald shafts and the time of opening of the shed. SRemove the knurled nut 24 and mount the circular cam 1 as shown in figure 11. The results showed that for the particular geometry tested tappetbore.

For the most part the test methods were based on procedures followed by the engine builders for studying cam and lifter materials and design. The objective of the experiment is to investigate tappet motion for several cam profiles and to see the effect of different followers. The purpose of this experiment is to investigate tappet motion for several different cam profiles and the effect of using different followers.

In the present study the frictional force between the cam and tappet is directly measured using a load sensor installed in a test rig and the following is carried out. Cam mechanisms are integral parts of many products. Department of Energy Office of Scientific and Technical Information.

SRemove the knurled nut 24 and mount the circular cam 1 as shown in figure 11. A cam and tappet mechanism comprising a straight reciprocating rod a compression spring on the rod for projecting it a-tappetlever hinged at one end and having an aperture near its opposite end through which the rod freely passes a nut on the upper or outer end of the rod a strong spring engaging the inner side of the tappet lever and holding it firmly against the nut. To compare the throw profile of two types of cams simple harmonic parabolic cam and tangent cam with two types of followers flat follower and dome follower.

Therefore tribological cambucket tappet component Stribeck tests were used to determine the friction behavior of ultrashort pulse laser fabricated microtextures and PVDPECVD deposited. A mechanical constraint cam also be introduced by employing a dual or conjugate cam in arrangement similar to what shown in Figure 6-7. Firstly the changes of friction with valve spring load camshaft revolution speed and oil temperature are examined for current materials and CD-level oil of diesel engines.

Tappets are generally used for heald shedding. Data For Convex cam. Sophisticated instrumentation has been used to measure the velocities and synchronize them with the lift event.

A follower is used to transfer the motion to the required machine part. The relative sliding of tappet roller to cam has been experimentally determined by means of a simulator rig.

Cam Tappet Contact Force Download Scientific Diagram

Lubricants Free Full Text Lubrication Analyses Of Cam And Flat Faced Follower Html

Cam Follower Mechanism Mechanical Kinematics Engineering Cam Gtu Youtube

Testing Of Cam Roller Follower Systems About Tribology

Testing Of Cam Roller Follower Systems About Tribology

Beat Up Mechanism In Weaving Weaving Shuttle Loom Motion

Testing Of Cam Roller Follower Systems About Tribology

Beating Mechanism With Sley Loom Weaving Weaving Loom

Lubricants Free Full Text Understanding Friction In Cam Tappet Contacts An Application Oriented Time Dependent Simulation Approach Considering Surface Asperities And Edge Effects Html

Loom Timing Diagram Basic Concepts Loom Engineering Colleges

Lubricants Free Full Text Lubrication Analyses Of Cam And Flat Faced Follower Html

Schematic Of A Cam Tappet Contact Configuration Download Scientific Diagram

The Motored Single Cam Rig A Photograph Of The Rig B 2d Schematic Download Scientific Diagram

Testing Of Cam Roller Follower Systems About Tribology

Cam Tappet Contact Force Download Scientific Diagram

Pin On Textile Flowchart All About Flow Chart Of Textile